Zhejiang Youji Machinery Technology Co.,Ltd >> Product >> Valve fittings >> Electric Actuator >> Express open/closed Electric Actuators

Zhejiang Youji Machinery Technology Co.,Ltd >> Product >> Valve fittings >> Electric Actuator >> Express open/closed Electric Actuators

Express open/closed Electric Actuators

Message If you want any further detail data and drawing,please contact us.

1.Summary

"AOX" series electric actuator is used for controlling 0°~270°rotation of the valves and other similar products, such as butterfly valve, ball valve, damper, flapper valves, cock valves, etc. It’s widely used in petroleum, chemical, water treatment, shipping, paper making, power plants, heating, light industry and other industries. It drives by 380V/220V/110V AC power. Control signal is 4-20mA current signal or 0-10V DC voltage signal, enables move the valve to the desired position, achieving its automation, maximum output torque is up to 4000N•m.

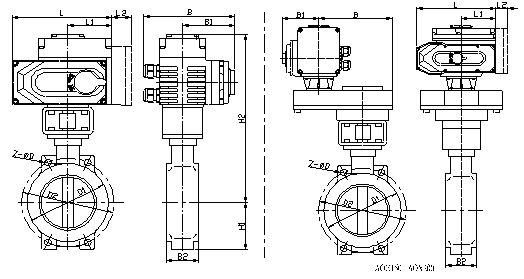

5.Installation Size

|

DN |

L |

L1 |

L2 |

B |

B1 |

B2 |

H1 |

H2 |

D1 |

D2 |

D |

Remark |

|

50 |

162 |

71.5 |

40 |

145 |

83.5 |

42.6 |

70 |

297 |

92 |

125 |

18 |

AOX05 |

|

65 |

162 |

71.5 |

40 |

145 |

83.5 |

45.6 |

76 |

310 |

106 |

145 |

18 |

AOX08 |

|

80 |

190 |

82 |

40 |

163 |

75 |

45.6 |

89 |

331 |

122 |

160 |

18 |

AOX10 |

|

100 |

190 |

82 |

40 |

163 |

75 |

51.6 |

104 |

348 |

150 |

180 |

18 |

AOX15 |

|

125 |

268 |

117 |

40 |

211 |

92.5 |

55.6 |

120 |

428 |

177 |

210 |

18 |

AOX20 |

|

150 |

268 |

117 |

40 |

211 |

92.5 |

55.6 |

132 |

447 |

204 |

240 |

23 |

AOX30 |

|

200 |

268 |

117 |

40 |

211 |

92.5 |

59.6 |

167 |

481 |

260 |

295 |

23 |

AOX40 |

|

250 |

268 |

117 |

40 |

211 |

92.5 |

67.6 |

202 |

520 |

314 |

350/355 |

23/26 |

AOX60 |

|

300 |

268 |

117 |

40 |

211 |

92.5 |

77.6 |

239 |

548 |

370 |

400/410 |

23/26 |

AOX80 |

|

350 |

268 |

117 |

40 |

211 |

92.5 |

79 |

265 |

583 |

422 |

460/470 |

23/26 |

AOX100 |

|

400 |

268 |

117 |

40 |

211 |

92.5 |

105 |

297 |

615 |

473 |

515/525 |

26/30 |

AOX160 |

|

450 |

268 |

117 |

40 |

250 |

119 |

112 |

331 |

819 |

526 |

565/585 |

26/30 |

AOX200 |

|

500 |

268 |

117 |

40 |

250 |

119 |

129 |

361 |

847 |

577 |

620/650 |

26/33 |

AOX200 |

2.Performance Features

2.1 Shell

The shell is made of horniness aluminium alloy, pass through anodic oxidation treatment and polyester powder coating, so it has strong corrosion resistance. Protection grade is IP67,NEMA 4 AND 6, and optional IP68 type.

2.2 Electric Machinery

Fully enclosed Squirrel-cage electric Machinery, small volume, large torque, and small inertia force, F-class insulation rating, inside hot protection switch, avoid damaging the electric machinery.

2.3 Manual Structure

The design of handle ensure safe, reliable, labor-saving, small volume. When it don’t have electricity, it can be manually operated by handle. When you don't operate by manus, you can put the spanner in the spanner folder, then you can easy to use it.

2.4 Indicator

Indicator installs in the center axis, so it can observes the valve position. It adopts convex mirror design, no cumulate water, more convenient to observe.

2.5 Space heater

It is used for controlling temperature, avoiding internal moisture of electric actuator condensed because of the changing of temperature and weather,keep inner electric device dry.

2.6 Sealing

Good sealing performance, and the protection class of standard product is IP67, and optional IP68 protection grade.

2.7 Limit switch

Mechanical, electronic double limit. Mechanical limit screw is adjustable, safe and reliable; electron limit switch is controlled by the cam mechanism, easy adjustment institutions can set the position accurately and conveniently, and it doesn’t affect overly by handwheel.

2.8 Self-locking

Exact worm and worm gear can efficiently transfer large torque, high efficiency, low noise (max. 50 dB), long life, and it has self-locking function to prevent the inversion, transmission part is stable and reliable, no need to add oil.

2.9 Anti-off bolt

When removed the shell, the bolt would be attached to the shell and didn’t fall off.

2.10 Install

The installation size of the bottom conforms to the international standard ISO5211 / DIN3337, The holes are double square so that it’s easy to fix the linear or 45°corner valves attached square bar, adaptable. It can be installed vertically, and also can be installed level.

2.11 Circuitry

Control circuit conforms to the single-phase or three-phase power supply standard, reasonably compact line layout, wiring terminals can effectively satisfy a variety of additional functional requirements.

3.Performance Parameter

|

Model |

Max output torque |

90°Operating time |

Output axis |

Electrical machinery |

Single-phase rated current(A)50HZ |

Weight |

|

|

Square |

Round |

||||||

|

N·M |

S |

mm |

W |

220V |

Kg |

||

|

AOX-005 |

50 |

30 |

11×11 |

Φ12.6 |

10 |

0.25 |

3.6 |

|

14×14 |

|||||||

|

AOX-008 |

80 |

30 |

11×11 |

Φ15.7 |

10 |

0.25 |

3.6 |

|

14×14 |

|||||||

|

AOX-010 |

100 |

30 |

14×14 |

Φ15.7 |

15 |

0.35 |

4.6 |

|

17×17 |

Φ18.95 |

||||||

|

AOX-015 |

150 |

30 |

14×14 |

Φ18.95 |

15 |

0.37 |

4.6 |

|

17×17 |

|||||||

|

AOX-020 |

200 |

30 |

22×22 |

Φ22.13 |

45 |

0.3 |

13 |

|

AOX-030 |

300 |

30 |

22×22 |

Φ28.48 |

45 |

0.31 |

13.4 |

|

AOX-040 |

400 |

30 |

22×22 |

Φ28.48 |

60 |

0.33 |

13.8 |

|

AOX-060 |

600 |

30 |

27×27 |

Φ31.65 |

90 |

0.33 |

14 |

|

AOX-080 |

800 |

45 |

27×27 |

Φ31.65 |

180 |

0.47 |

14.3 |

|

AOX-100 |

1000 |

135 |

27×27 |

Φ31.65 |

180 |

0.47 |

60 |

|

AOX-160 |

1600 |

135 |

Max φ65 |

180 |

0.85 |

60 |

|

|

AOX-200 |

2000 |

135 |

Max φ65 |

180 |

0.85 |

60 |

|

|

AOX-300 |

3000 |

135 |

Max φ65 |

180 |

0.85 |

60 |

|

4.Standard Technical Parameter

|

Shell |

Aluminium alloy Shell, waterproof leve:IP67,NEMA4 and 6 |

|

|

Power supply |

110/220V AC 1Phase,380/440V AC 3Phase, 50/60Hz, ±10% |

|

|

Control supply |

110/220V AC 1Phase,50/60 Hz, ±10% |

|

|

Electric Machinery |

Squirrel-cage Asynchronous electric Machinery |

|

|

Limit switch |

2 X On/ Off,SPDT,250V AC 10A |

|

|

Accessorial Limit switch |

2 X On/ Off,SPDT,250V AC 10A |

|

|

Stroke |

90°~270°±10°(When it’s over 90°,please note us in advance) |

0°~270° |

|

Speed protection/ |

Inside hot protection, On 120℃ ±5℃/Off 97℃ ±15℃ |

|

|

Indicator |

Continuous situation indication |

|

|

Manul operation |

Mechanical handle(Optional:Fixing with the handwheel ) |

|

|

Self-locking device |

Provide self-locking by worm and worm gear |

|

|

Mechanical Limit |

2 pieces of adjustable bolts |

|

|

Space heater |

7-10W (110/220V AC) Condensation-preventing |

|

|

Bonding hole |

2個(Pieces) M18 |

|

|

Ambient temperature |

-20℃--+70℃ |

|

|

Lubrication |

Aluminium base grease(EP) |

|

|

Material |

Steel, Aluminium alloy, Aluminium bronze, Polycarbonate |

|

|

Ambient humidity |

Max 90% RH |

Non-Condensed |

|

Shock Survial |

X Y Z 10g,0.2~34 Hz,30 minutes |

|

|

External coating |

Dry powder, Epoxy polyester |

|